- Overview

- Recommended Products

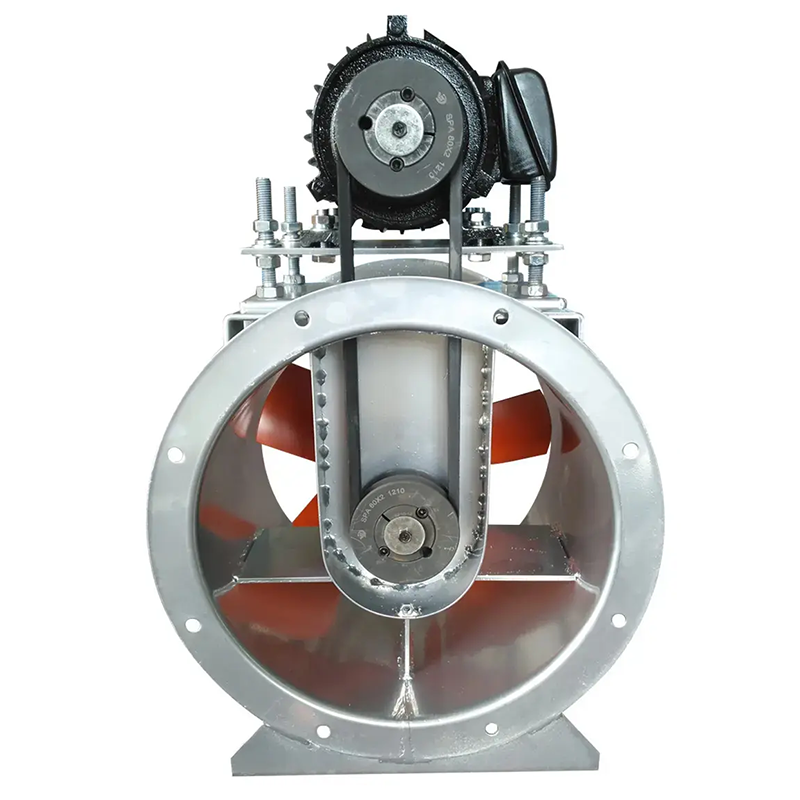

1、 Core structure and working principle drive system

Belt drive mechanism: The drive wheel is connected to the output shaft of the electric motor, and the power is transmitted to the driven wheel through a belt (commonly V-shaped or toothed belt) to drive the fan impeller to rotate.

Speed ratio adjustment: By adjusting the diameter ratio of the main/driven wheels (usually 1.5:1 to 3:1), decoupling control of impeller speed and motor speed is achieved to meet different air volume requirements.

Advantages: Avoid high starting torque impact caused by direct connection of motors and extend equipment life.

Aerodynamic Design

Axial flow impeller: using wing or plate blades, the airflow moves along the axis direction, and the efficiency can reach 78-85%.

Low pressure and high-speed characteristics: suitable for high air volume requirements (5000-50000 m ³/h) and low static pressure requirements (fan: fan efficiency; η belt: belt transmission efficiency*

Belt selection specifications

V-belt: suitable for power ≤ 75 kW and ambient temperature < 40 ℃

Synchronous toothed belt: High precision, lubrication free, suitable for precision speed regulation scenarios