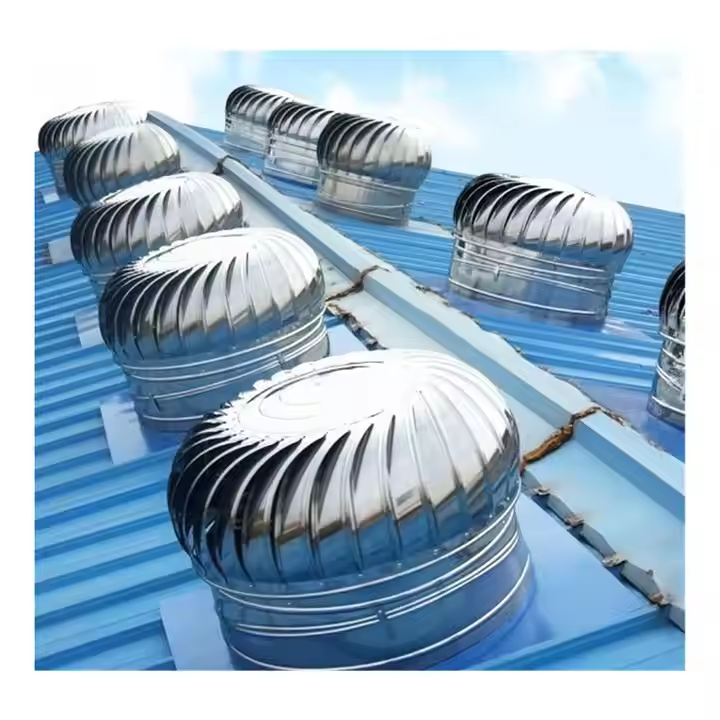

Understanding Roof Fan Performance and Common Failure Points

How Dust Buildup Impacts Roof Fan Efficiency

When dust builds up on roof fans, it actually makes them perform worse because the blades get heavier and their aerodynamics become messed up. The latest HVAC Efficiency Report from 2025 found something pretty significant: if dust accumulates over 1.5 mm thick, airflow drops about 22% while energy use jumps around 30%. What happens when particles settle unevenly? The blades become unbalanced, which means motors have to push harder just to keep spinning at the same speed. This extra strain wears out important parts much faster than normal operation would allow.

Key Mechanical Components Prone to Wear in Roof Fans

Three components account for 78% of roof fan failures (Mechanical Systems Journal 2024):

- Bearings: Inadequate lubrication leads to friction and overheating

- Motor Windings: Voltage fluctuations degrade insulation over time

- Blade Brackets: Continuous vibration causes metal fatigue and weakens attachments

Regular inspections using infrared thermometers and vibration analysis tools help detect early signs of wear in these high-risk areas, preventing unexpected breakdowns.

Identifying Early Signs of Roof Fan Performance Degradation

Operators can prevent 65% of catastrophic failures (FM Global 2023) by monitoring for early warning signs:

- Intermittent humming during startup, indicating capacitor degradation

- Blade tip wobble exceeding 3 mm

- Current draw fluctuations over 15% from baseline

A case study from a warehouse in Qatar showed that monthly performance logging reduced unplanned downtime by 41%, demonstrating the value of consistent monitoring for early intervention.

Essential Cleaning and Blade Maintenance for Optimal Airflow

Effective Roof Fan Cleaning Methods to Prevent Dust Accumulation

When dust builds up on roof fan systems, it can cut down airflow by as much as 40% according to the HVAC Efficiency Report from last year. To start cleaning, make sure the power is turned off first, then blast away any loose dirt with compressed air around the blades and inside the housing area. For those really stuck-on bits, grab some gentle solvent solutions and wipe them down with microfiber cloths. Stay clear of anything abrasive since it might scratch off protective finishes. After loosening everything up, run a good quality HEPA filtered vacuum through the system to suck out nearly all the particles that have come loose. Maintenance shops tell us that when they clean their fans roughly every three months, components tend to last about 25% longer before needing replacement.

Step-by-Step Blade Cleaning and Imbalance Prevention

- Remove visible debris with plastic scrapers

- Clean blade grooves in an ultrasonic bath (30-minute cycle recommended)

- Check balance using laser alignment tools (tolerance >0.002")

- Apply anti-static coating to minimize future dust adhesion

Imbalanced blades increase bearing load by 18% (Fan Engineering Handbook), making quarterly balancing essential. Installing vibration sensors allows real-time detection of mass deviations before performance is affected.

Seasonal Cleaning Schedules and Safety Protocols for Roof Fans

| Season | Maintenance Focus | Safety Priority |

|---|---|---|

| Spring | Post-pollen filter replacement | Arc flash prevention |

| Summer | Condensation drain clearing | Heat stress monitoring |

| Fall | Bearing lubrication refresh | Fall arrest systems |

| Winter | Ice dam prevention | Slip hazard mitigation |

Always implement lockout/tagout procedures during maintenance. Technicians working above 6 feet must use Class II harnesses. Facilities following ASHRAE Standard 180-2023 report 62% fewer unplanned downtime incidents.

Mechanical Adjustments: Belt Tensioning, Alignment, and Drive System Care

Proper belt tensioning techniques to maximize roof fan efficiency

Getting belt tension right makes all the difference when it comes to saving energy and making sure components last longer. Most industrial fans run around 8 to 12 hours each day, so proper tension means allowing about half an inch to three quarters of an inch sag right in the middle where the belt sits between the pulleys. A good practice is to grab a tension gauge and check against what the manufacturer recommends in their specs sheet. When belts get too tight, bearings take on extra stress that can jump up to 30 percent according to Industrial Drive Systems research from 2022. On the flip side, if belts are too loose they start slipping instead of gripping properly, which cuts down on airflow somewhere between 15 and 20 percent. Finding that sweet spot really pays off in both performance and maintenance costs over time.

Diagnosing misalignment and slippage using vibration analysis

Vibration levels above 0.25 in/sec RMS typically signal drive system issues. Portable analyzers identify specific fault patterns:

- Parallel misalignment: dominant 2x RPM harmonics

- Angular misalignment: elevated 1x RPM peaks

- Belt slippage: random high-frequency spikes

Thermal imaging complements vibration data by revealing overheated couplings or pulley bearings, enabling proactive repairs before failure occurs.

Maintenance checklist for pulleys, couplings, and drive alignment

| Component | Inspection Frequency | Key Checks |

|---|---|---|

| V-Belts | Monthly | Cracking, glazing, tension |

| Pulleys | Quarterly | Wear grooves, alignment with laser tools |

| Couplings | Biannually | Bolt torque, spacer gap consistency |

| Motor mounts | Annually | Rust, fastener integrity, shim condition |

Realign the entire drive system whenever replacing belts, as 68% of premature failures stem from misalignment after repairs.

Roof Fan Maintenance: Ensuring Long-Term Performance

Preventing Motor Failures: Capacitor and Bearing Maintenance

Testing and Replacing Roof Fan Capacitors to Avoid Startup Failure

Capacitors degrade 8-10% annually due to heat exposure, making biannual testing essential. Use a multimeter to verify capacitance within ±10% of manufacturer specifications. Replace units showing over 15% deviation or physical bulging. Timely replacement reduces motor startup failures by 73% (HVAC Reliability Report 2022).

Bearing Lubrication Schedules and Grease Compatibility Best Practices

High-temperature lithium-complex greases last 2.8 times longer than conventional oils in rooftop environments. Re-lubricate every 4,000 operating hours or quarterly—whichever comes first. Follow this process:

- Purge old grease through dedicated ports

- Fill to one-third housing capacity with fresh grease

- Monitor amperage post-lubrication (increase should not exceed 5%)

Using Infrared Thermography to Detect Early Bearing Overheating

Quarterly infrared scans detect temperature differences of ≥9°F (5°C) across bearings—often the first sign of impending failure. These thermal anomalies correlate with 89% of bearing issues (Predictive Maintenance Benchmark Study 2023). Combine thermography with vibration analysis (threshold: 0.15 in/sec RMS) to prioritize repairs effectively.

Comprehensive Preventive Maintenance Plans and Long-Term Optimization

Monthly, Quarterly, and Annual Roof Fan Inspection Checklists

Having a regular inspection plan really makes a difference in how long equipment lasts and how dependable it stays over time. For monthly stuff, workers need to look around for any dirt buildup or strange vibrations that might indicate problems. Every three months brings bigger tasks like checking belt tightness, taking temperature readings on bearings, and making sure there's enough lubricant everywhere it needs to be. Once a year comes the big checkup where everything gets tested from top to bottom including motors and airflow systems throughout the facility. Plants that stick with this kind of planned maintenance spend about 18 to 22 percent less on repairs than those waiting until something breaks down first, according to research published last year by Ponemon Institute.

Airflow Diagnosis and Duct Sealing to Eliminate Performance Losses

Checking for air leaks regularly with tools like anemometers or thermal cameras can catch problems that might be cutting system efficiency down by as much as 30%. When we find those gaps in ductwork, sealing them properly with good quality mastic compound helps keep the static pressure stable and makes everything run better. The National Institute of Standards and Technology did some research recently showing buildings saved between 15 and 20 percent on energy costs after fixing their HVAC issues last year. Another important step is making sure the airflow gets distributed evenly among all those roof mounted fans. This keeps motors from working too hard and extends their lifespan significantly.

Upgrading to EC Motors and VFDs for Adaptive, Energy-Efficient Roof Fan Operation

Switching from standard AC motors to electronically commutated EC models can cut energy usage anywhere between 35 to 40 percent, plus these motors offer much better control over speed settings according to the Department of Energy report from 2024. Pair them with variable frequency drives and they become even more efficient, letting systems adjust airflow based on actual needs which means blades wear out half as fast compared to older systems. The upfront costs run around $1,200 to $1,800 for each motor replacement, but many businesses find that their electricity savings plus longer lasting equipment typically pays back this expense within just under two years operationally speaking.

FAQ

How often should roof fans be cleaned to maintain efficiency?

Ideally, roof fans should be cleaned every three months to prevent dust buildup and maintain efficient airflow.

What are the main causes of roof fan failures?

The main causes of roof fan failures include inadequate lubrication of bearings, voltage fluctuations affecting motor windings, and metal fatigue in blade brackets.

How can I detect early signs of wear in roof fans?

Early signs of wear can be detected through infrared thermometers and vibration analysis tools to monitor changes in components like bearings and motors.

What benefits do EC motors and VFDs provide for roof fans?

EC motors and VFDs provide adaptive and energy-efficient operation, reducing energy usage by 35 to 40 percent, and offering better control over speed settings.

Table of Contents

- Understanding Roof Fan Performance and Common Failure Points

- Essential Cleaning and Blade Maintenance for Optimal Airflow

- Mechanical Adjustments: Belt Tensioning, Alignment, and Drive System Care

- Roof Fan Maintenance: Ensuring Long-Term Performance

- Comprehensive Preventive Maintenance Plans and Long-Term Optimization

- FAQ