Understanding Upblast Fans: How They Work and What Sets Them Apart

What is an upblast fan and how does it enable vertical exhaust?

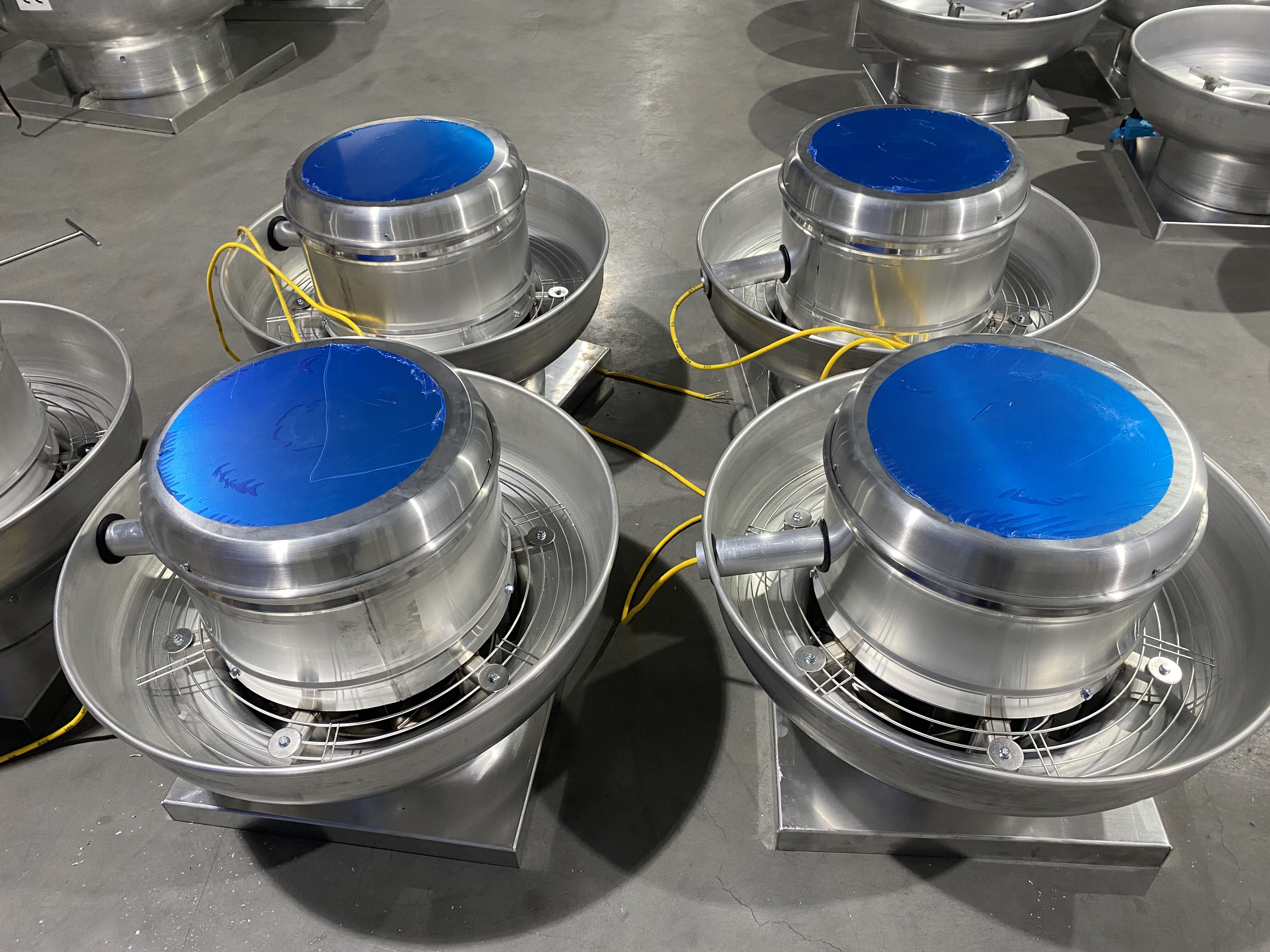

Upblast fans sit on rooftops as exhaust systems that pull air, heat, and stuff we don't want straight up and out of buildings. These differ from downblast versions which blow air down instead. Upblast models work by creating what's called a chimney effect through their upward airflow pattern. This makes them really important for places like restaurants where all that greasy vapor needs to escape safely. The fans have these curved blades that spin around and create force to move air fast - sometimes as much as 3,000 cubic feet per minute. They also come with special covers that stop rain from getting inside. Most newer models (about 78% according to ASHRAE numbers from last year) now place motors outside the airstream path. This protects vital parts from both grease buildup and extreme temperatures. Even when things get hot enough to cook an egg on metal surfaces, these fans keep working reliably thanks to this design feature.

Types of Upblast Fans: Matching Motor Design and Drive Systems to Your Needs

Axial vs. Centrifugal Upblast Fans: Airflow Volume and Pressure Capabilities

When deciding between axial and centrifugal upblast fans, it really comes down to what kind of airflow and pressure is needed for the job. Axial fans work by moving air along the same line as the motor shaft, which gives them that big volume output range of around 8,000 to 15,000 cubic feet per minute but keeps the static pressure pretty low, usually below half an inch. These types are great for ventilating big spaces like warehouses where massive amounts of air need to be moved without much resistance. On the other hand, centrifugal upblast fans have those spinning impellers that create much higher pressure levels, typically between one and two and a half inches. This makes them perfect for industrial applications where there's thick smoke or lots of particles in the air that need to be pulled out efficiently from manufacturing environments.

| Feature | Axial Upblast Fans | Centrifugal Upblast Fans |

|---|---|---|

| Max Airflow Capacity | 15,000 CFM | 6,500 CFM |

| Pressure Range | 0.1–0.5" SP | 0.75–2.5" SP |

| Energy Use | 12–18 kW | 18–30 kW |

Direct-Drive Upblast Fans: Simplicity, Efficiency, and Low Maintenance

Direct-drive upblast fans connect the motor directly to the blade, eliminating belts and pulleys. This design achieves 92–95% mechanical efficiency and has 40% fewer moving parts than belt-drive systems, reducing maintenance to biannual bearing lubrication. Best suited for continuous-duty environments like commercial kitchens, they perform optimally below 2,000 CFM and 0.5" SP.

Belt-Drive Upblast Fans: Handling High-Torque Demands in Industrial Settings

Belt-drive configurations allow RPM customization through pulley ratios, supporting torque outputs up to 450 N·m—ideal for heavy industrial operations such as foundries or chemical processing plants. While requiring quarterly tension checks, these systems operate 10–15 dB quieter than direct-drive models at equivalent airflow levels.

Comparing Drive Systems: Lifespan, Noise, Energy Use, and Serviceability

| Factor | Direct-Drive | Belt-Drive |

|---|---|---|

| Average Lifespan | 12–15 years | 8–12 years |

| Noise Level | 68–72 dBA | 58–65 dBA |

| Service Intervals | 6 months | 3 months |

| Energy Cost/Year | $1,200–$1,800 | $1,500–$2,200 |

Facilities focused on energy efficiency typically prefer direct-drive systems, whereas those needing variable speed control opt for belt-drive despite increased maintenance demands.

Key Selection Criteria for Optimal Upblast Fan Performance

Sizing Your Upblast Fan: Calculating Required CFM Based on Facility Volume

Getting the right size fan begins by calculating what kind of airflow is actually needed. The basic math goes something like this: CFM equals facility volume multiplied by air changes per hour divided by sixty. Most warehouse spaces tend to work well with around fifteen to twenty air changes throughout the day. But when we're talking about laboratory environments where chemical fumes are a concern, those numbers jump up significantly, often hitting thirty or even higher to properly remove harmful substances from the air. When fans aren't sized correctly, problems start piling up fast. Too small a unit strains the motor constantly, leading to breakdowns sooner rather than later. On the flip side, installing something too big just wastes electricity without delivering better results. According to recent studies published by ASHRAE in 2023, about one out of every four early equipment failures can be traced back directly to incorrect fan sizing decisions.

Ventilation Requirements by Application: Warehouses, Labs, and Commercial Kitchens

Application-specific needs dictate fan specifications. Commercial kitchens demand stainless steel construction and UL 762 compliance, with typical airflow ranging from 1,500–3,000 CFM per hood section based on HoodMart 2023 standards. Pharmaceutical labs require spark-resistant motors and compatibility with HEPA filtration, while warehouse ventilation prioritizes high-volume, low-static-pressure performance.

Environmental Factors: Corrosion Resistance, Temperature Extremes, and Weather Exposure

In coastal areas, galvanized steel or aluminum housings with IP55 ratings provide essential protection against salt corrosion. For Arctic climates, motors must operate reliably at -40°F. Rain hoods with 360° overshoot collars reduce water intrusion by 89% compared to basic designs, enhancing durability in harsh weather.

Ensuring Code Compliance: IMC, NFPA, and UL 762 Standards for Safe Operation

All upblast fans must meet International Mechanical Code (IMC) airflow requirements and NFPA 96 fire safety standards. UL 762 certification ensures 98% grease containment efficiency—significantly higher than the 76% seen in non-certified units—making it a critical factor in minimizing fire risks in commercial kitchens.

Top Applications of Upblast Fans in Commercial and Industrial Facilities

Commercial Kitchen Ventilation: Managing Heat, Smoke, and Grease-Laden Air

In busy commercial kitchens where grills and fryers run for around 12 hours straight each day, upblast fans become a real necessity. These powerful units can move as much as 3,000 cubic feet of hot, greasy air per minute from cooking equipment. According to the latest findings from the 2024 Commercial Ventilation Report, models that meet UL 762 standards cut down on fire hazards by almost 80% when compared to regular systems that aren't specifically designed for kitchen environments. The vertical discharge design helps keep those pesky grease deposits from accumulating inside the ductwork, which is a big plus for maintenance crews. Plus, the housing materials resist corrosion even when exposed to extreme heat levels reaching up to 500 degrees Fahrenheit or 260 Celsius. That kind of durability makes all the difference in high-traffic kitchen operations.

UL 762 Compliance and Grease Handling: Critical for Kitchen Safety

The NFPA 96 standard calls for less than 500 microns of grease residue in exhaust streams, which means UL 762 compliant upblast fans need some serious engineering. These fans typically feature three main components that make them work so well: first, they have those special aluminum impellers that resist sparking, then there are those curved surfaces on the housing that drain grease naturally instead of letting it build up, and finally, most models use 16 gauge stainless steel throughout their construction. When tested under real conditions, certified versions trap around 94% of those dangerous flaming grease particles when things get hot enough to cause flare ups. That makes a huge difference in preventing those nasty rooftop fires we all hear about from time to time.

Common Installation Locations: Rooftops, Exhaust Hoods, and Stack Connections

Over 82% of food service facilities install upblast fans on rooftops for optimal performance. This location offers unobstructed airflow and full access for maintenance.

| Installation Point | Airflow Efficiency | Maintenance Accessibility |

|---|---|---|

| Rooftop | 95% unobstructed | Full component access |

| Exhaust Hood | 87% efficiency | Partial access challenges |

| Stack Connection | 91% efficiency | Specialized equipment needed |

Rooftop placement supports 20–30 air changes per hour in 500–800 sq ft kitchens, which has been shown to lower ambient temperatures by 15°F (8.3°C), improving comfort and safety.

Maximizing Longevity and Efficiency: Maintenance and Operational Best Practices

Routine maintenance: Cleaning, inspection, and lubrication schedules

Fans last almost 20% longer when we stick to regular maintenance rather than waiting until something breaks down, according to FCAP Group research from last year. Every week, take a quick look at those blades to spot any cracks or chips, and make sure nothing is clogging up the airflow. For restaurants and other places with heavy cooking activity, getting those fans professionally cleaned twice a year really makes a difference in keeping all that greasy stuff from building up inside. And don't forget about the oil! Putting high temp grease on those motor bearings once every three months helps them run smoother and lasts much longer. Most technicians will tell you worn out bearings are actually what causes most rooftop unit failures in the first place.

Preventing common failures in belt-driven upblast fan systems

Misaligned belts cause 60% of belt-drive failures (Industrial Fan Report 2024). To avoid this:

- Test belt tension monthly using deflection tools

- Replace belts in pairs to maintain balance

- Check pulley alignment quarterly with laser tools

Thermal imaging during operation can detect overheating bearings early, preventing up to 80% of major motor failures.

Smart monitoring and predictive maintenance technologies for upblast fans

When vibration sensors get connected to IoT platforms, they cut down on unexpected equipment shutdowns by around 35 percent according to FanTech Journal from last year. These smart systems can spot problems like imbalances or worn bearings before they cause major issues. Some of the newer technologies look at how much electricity motors are using along with changes in air movement patterns to forecast when blades might start eroding in harsh chemical environments. For kitchens needing to follow safety regulations, cloud based maintenance management software handles things like reminding staff when it's time for oil changes or replacing parts. This automation makes sure everything stays compliant with those tricky NFPA 96 standards that govern restaurant ventilation systems.

Frequently Asked Questions (FAQ)

What is the primary function of an upblast fan?

The primary function of an upblast fan is to expel air, heat, and unwanted substances vertically out of a building, often used in environments like restaurants to remove grease-laden air safely.

What is the difference between axial and centrifugal upblast fans?

Axial upblast fans move air along the same line as the motor shaft and are suitable for high-volume, low-pressure applications. Centrifugal upblast fans, with spinning impellers, are designed for higher pressure levels, ideal for industrial settings with dense smoke or particles.

How do direct-drive and belt-drive upblast fans differ?

Direct-drive upblast fans have motors connected directly to blades, providing simplicity and high efficiency with less maintenance. Belt-drive models allow for RPM customization to handle higher torque demands but require more regular maintenance.

Why is UL 762 compliance important for upblast fans in kitchens?

UL 762 compliance ensures higher grease containment efficiency, minimizing fire risks in commercial kitchens by adhering to safety and performance standards, crucial for kitchen ventilation systems.

How can I maximize the lifespan of an upblast fan?

Regular maintenance, including cleaning, inspection, and lubrication, along with utilizing smart monitoring and predictive maintenance technologies, can significantly extend the life of an upblast fan.

Table of Contents

- Understanding Upblast Fans: How They Work and What Sets Them Apart

- Types of Upblast Fans: Matching Motor Design and Drive Systems to Your Needs

-

Key Selection Criteria for Optimal Upblast Fan Performance

- Sizing Your Upblast Fan: Calculating Required CFM Based on Facility Volume

- Ventilation Requirements by Application: Warehouses, Labs, and Commercial Kitchens

- Environmental Factors: Corrosion Resistance, Temperature Extremes, and Weather Exposure

- Ensuring Code Compliance: IMC, NFPA, and UL 762 Standards for Safe Operation

- Top Applications of Upblast Fans in Commercial and Industrial Facilities

- Maximizing Longevity and Efficiency: Maintenance and Operational Best Practices

- Frequently Asked Questions (FAQ)