Maximizing Airflow Efficiency with High-Performance Food Truck Fan Systems

The Role of Food Truck Fan in Kitchen Ventilation and Heat Management

Effective food truck fan systems remove grease-laden air while introducing fresh airflow, maintaining compliance with health codes and operator safety. Properly sized ventilation prevents ambient temperatures from exceeding 125°F (52°C) during peak service—a critical threshold for equipment longevity and staff productivity.

Understanding CFM Ratings and Airflow Optimization in Mobile Units

Target 1,000–1,500 CFM (cubic feet per minute) for typical 50–80 sq ft kitchens, ensuring 15–20 complete air changes per hour. A 2023 thermal management study found that food trucks using CFM-optimized fans reduced refrigeration compressor failures by 60% compared to undersized systems, highlighting the importance of precise airflow calibration.

Variable Speed Controls and Smart Sensors for Adaptive Fan Performance

The latest fan systems in food trucks now incorporate VFD or Variable Frequency Drive motors. These motors can change their speed automatically depending on what's happening around them. They respond to things like how much smoke is building up, the temperature inside, when cooking equipment turns on, and even the moisture level outside. The way these systems work keeps the air moving just right through the kitchen area. When nothing's going on, they actually save quite a bit of power too, somewhere between 35% to maybe even half of what older models would use. So restaurants stay safe from overheating but also end up spending less on electricity bills in the long run.

Case Study: Reducing Heat Buildup in a Dallas Food Truck with Upgraded Fans

When a BBQ food truck operator in Dallas swapped out their old 800 CFM fan for a bigger 1,400 CFM model with blades that resist particles, they noticed something pretty amazing happening in the kitchen. Temperatures dropped nearly 30 degrees Fahrenheit, going from uncomfortable heat above 150°F down to a much more manageable 90-100°F range. This change didn't just make working conditions better either. The fried chicken fryers lasted almost a year and a half longer than before, and those annoying electrical problems caused by condensation? They basically disappeared, with equipment failures dropping by around three quarters. For anyone running a commercial kitchen, this shows just how important getting the right size ventilation system really is for day to day operations.

Durable, Mobile-Specific Components for Reliable Food Truck Fan Operation

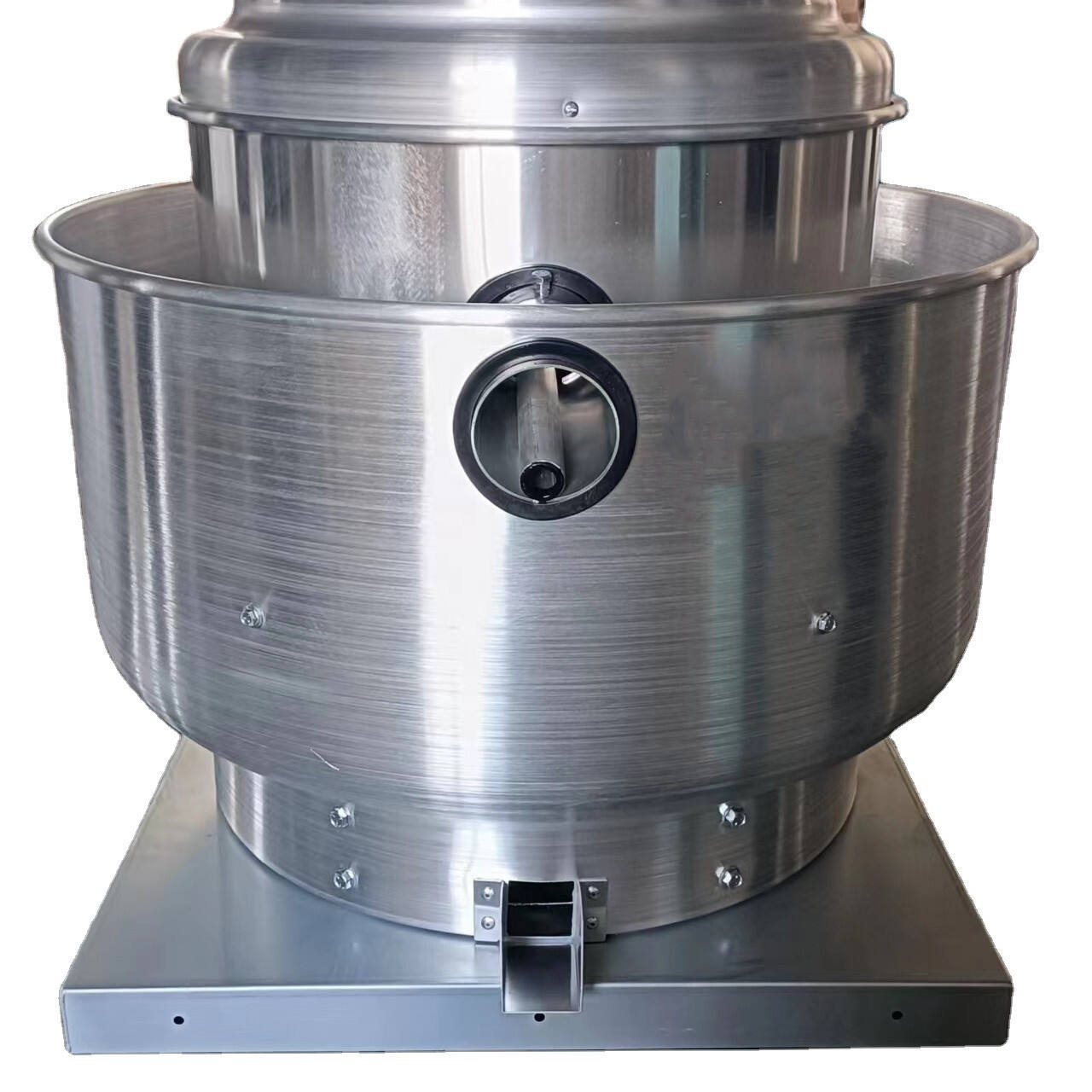

Weather-Resistant Housings and Corrosion-Proof Materials for Harsh Conditions

Anyone who runs a food truck knows they're constantly battling against grease buildup, dampness, and wild temperature swings. Most modern food trucks now come equipped with heavy-duty stainless steel enclosures and tough marine-grade aluminum parts that have stood up to saltwater tests for hundreds of hours without rusting. The powder coating on these surfaces helps keep oil and grime at bay while still letting air circulate properly. What really matters is how well these materials handle different weather conditions. They work great in places where temps can dip below freezing or soar past 200 degrees Fahrenheit, which makes all the difference when serving customers from beachside locations to desert towns.

Vibration Dampening Mounts to Ensure Stability During Transit

The constant shaking from roads actually causes around 38% of fans to fail early in those mobile kitchen setups. The newer isolation systems work pretty well though they mix neoprene padding together with springs mounted underneath, cutting down all that mechanical stress by about 72% when moving around. These special locking bolts really help stop things from coming loose even on bumpy roads, keeping vibrations under control at less than a tenth of an inch displacement. From what we've seen out in the field, this kind of mounting system makes bearings last nearly three times longer than just bolting everything down rigidly without any give.

Long-Lasting Motor Casings and Blades for High-Humidity Cooking Environments

The NEMA 4X motor casings come sealed with special coatings that keep out steam and greasy stuff. These coatings are both water repelling and fight against microbes growing on them. The blades themselves are curved from aluminum and measure around 0.08 inches thick. This thickness gives just the right mix between lasting power and how well they move air through the system. They won't warp even when exposed to really humid conditions where moisture levels hit over 90%. For the shafts, ceramic coatings make a big difference too. Tests show these coatings cut down on friction wear by almost two-thirds during constant operation. That means motors last longer without breaking down unexpectedly.

Energy-Efficient Power Solutions for Sustainable Food Truck Fan Performance

Modern food truck operations require ventilation systems that deliver strong cooling performance while minimizing energy consumption. Rising fuel costs and environmental standards are driving adoption of smarter, more sustainable fan technologies. Three key innovations are leading this shift.

Solar-Assisted Ventilation Systems Integrated with Food Truck Fan Units

Solar-powered ventilation integrates photovoltaic panels with fan units via micro-inverters and smart controllers that modulate fan speed based on sunlight availability. These systems can offset up to 40% of a food truck's energy use during daylight hours, reducing generator dependency and lowering operational costs.

Battery and Inverter Compatibility for Off-Grid Cooling Needs

High-capacity lithium-ion batteries paired with hybrid inverters enable uninterrupted fan operation during off-grid events or power fluctuations. Offering 3–5 times the energy density of lead-acid batteries, these systems support both 12V/24V DC and 120V AC configurations, ensuring reliable performance regardless of power source.

Balancing Power Consumption and Cooling Output: The Efficiency Challenge

Achieving optimal efficiency requires aligning motor power draw with airflow output. Brushless DC motors reduce energy consumption by up to 35% compared to traditional AC motors. When combined with variable speed controls, they allow dynamic adjustments—lowering RPM during low-activity periods while maintaining safe kitchen conditions.

Smart Monitoring and IoT-Driven Control for Advanced Food Truck Fan Management

Wi-Fi-Enabled Controllers for Remote Fan and Temperature Adjustment

Wi-Fi-enabled controllers allow operators to adjust ventilation settings remotely via smartphone or tablet. Integrated with temperature sensors, these systems automatically scale fan speeds during peak cooking or idle times. According to a 2024 industry report, food trucks using remote-controlled fans reduced energy waste by 22% while maintaining stable kitchen temperatures.

IoT Integration: Real-Time Alerts for Fan Malfunctions and Overheating

Fans connected to the Internet of Things send immediate alerts when something goes wrong with the motor, gets too hot, or starts acting strangely. The built-in sensors monitor things like how much force is on the blades, wear on the bearings, and how hard air has to push through, so problems can be caught early before they turn into big breakdowns. Take kitchens where deep fryers run hot as an example. When temps inside the cooking area go past around 145 degrees Fahrenheit (which happens all the time with those big fryers), the system kicks in extra cooling measures automatically to keep everything from getting too warm and causing damage.

Data-Driven Maintenance Using Fan Usage Analytics

Cloud-based dashboards track key metrics like runtime, power draw, and cycle frequency. Machine learning algorithms analyze this data to predict optimal maintenance intervals, particularly for filter replacements. This approach has reduced unplanned downtime by 37% in commercial mobile kitchens.

User-Friendly Mobile Apps for On-the-Go Food Truck Fan Settings

Intuitive mobile apps allow vendors to manage multiple fan zones and activate preset ventilation modes for frying, grilling, or baking. These customizable profiles ensure rapid response during high-demand periods, minimizing manual input and streamlining kitchen operations.

FAQs

Why is proper ventilation important in food trucks?

Proper ventilation in food trucks is crucial to maintain safe ambient temperatures, comply with health codes, prevent equipment failure, and ensure a comfortable working environment for staff.

What are some new technologies in food truck fans?

Recent innovations include variable speed controls, smart sensors, AI-powered airflow mapping, self-cleaning blade coatings, solar compatibility, and IoT integration for real-time management and monitoring.

How do variable speed controls improve fan efficiency?

Variable speed controls adjust fan speed based on cooking conditions, optimizing airflow and reducing energy consumption by up to 50% compared to fixed-speed systems.

Can fan systems be powered by alternative energy sources?

Yes, modern fan systems in food trucks can integrate with solar panels and batteries to reduce reliance on generators and minimize operational costs.

Table of Contents

- Maximizing Airflow Efficiency with High-Performance Food Truck Fan Systems

- Durable, Mobile-Specific Components for Reliable Food Truck Fan Operation

- Weather-Resistant Housings and Corrosion-Proof Materials for Harsh Conditions

- Vibration Dampening Mounts to Ensure Stability During Transit

- Long-Lasting Motor Casings and Blades for High-Humidity Cooking Environments

- Energy-Efficient Power Solutions for Sustainable Food Truck Fan Performance

- Smart Monitoring and IoT-Driven Control for Advanced Food Truck Fan Management

- FAQs