Blower Fan Fundamentals: Types, Working Principles, and Selection Criteria

Blower vs fan vs compressor: Key differences in function and design

Blower fans sit somewhere in the middle when comparing standard fans and compressors based on how much pressure they can produce. Regular fans move air around but only create pressure ratios under 1.11 according to those ASHRAE guidelines from last year, which works fine for basic ventilation needs. Blowers push things further with pressure ratios ranging from 1.11 to 1.2, giving them enough power to handle resistance in systems like those used for moving materials through pipes in factories. When we get to compressors, they go way beyond that threshold, typically hitting above 1.3 ratio for serious gas compression tasks. The difference in these pressure capabilities really shapes how each type is built. Blowers need stronger parts like reinforced impellers and fully enclosed housings, whereas regular fans have much simpler construction since they don't deal with such intense forces.

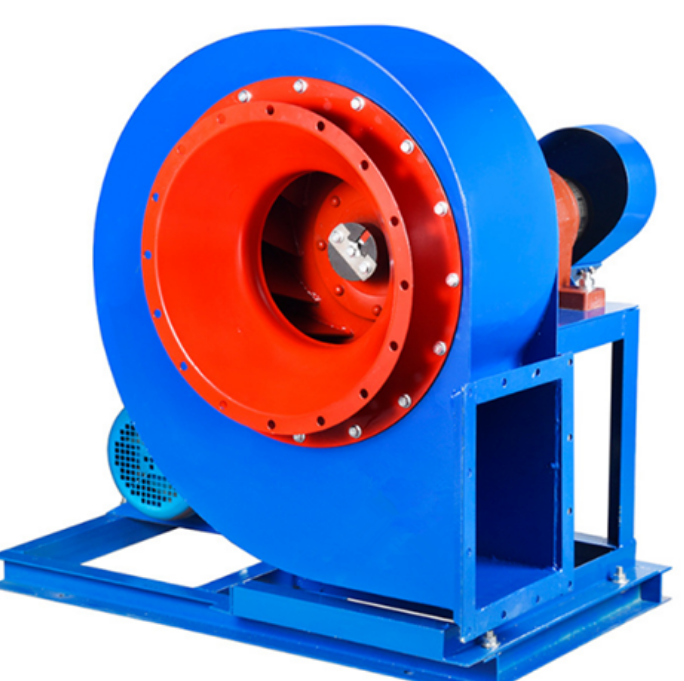

Centrifugal vs positive displacement blower fans: How they work and where they excel

Centrifugal blowers work by spinning impellers that push air outward, creating consistent airflow at pressures between 30 and 150 kPa. These are great for places where cleanliness matters most, such as heating and cooling systems. On the other hand, positive displacement blowers including rotary lobe and screw designs function differently. They capture specific amounts of air and then release them, making them better suited for situations requiring higher pressure levels around 200 kPa. Think about wastewater treatment plants needing constant aeration or when materials need to be moved through pipes under pressure. Recent research looked at performance data from over 40 factories last year and discovered something interesting about energy efficiency. When dealing with systems that experience regular changes in pressure demand, positive displacement models actually consume about 18 percent less power compared to their centrifugal counterparts according to this industry analysis.

Selecting the right blower fan based on pressure, airflow, and system requirements

Key selection criteria include:

- Operating pressure: PD blowers sustain 15–35% higher pressures than centrifugal models

- Airflow consistency: Centrifugals perform better in stable, low-variability conditions (≥92% uptime)

- Pulsation tolerance: PD blowers handle 3–5 times more pressure fluctuation

Always match manufacturer performance curves to actual system resistance; undersizing increases energy costs by an average of 22% (Pneumatic Systems Journal 2023).

How Blower Fans Enable Efficient Material Transport in Pneumatic Conveying

Blower fans work by creating a controlled pressure difference that moves bulk materials such as powders, grains, and pellets along enclosed pipelines. These systems cut down on the need for manual labor, help prevent damage to products during transport, and reduce the chances of contamination. Take pharmaceutical manufacturing as an example where these blowers are essential. They handle delicate powders moving them at impressive speeds around 25 meters per second without breaking down the particles themselves. Looking at market trends, the demand for pneumatic conveying blowers has been increasing steadily. Since 2021, the global market for these devices has seen growth rates hovering around 12% each year. This upward trend makes sense when we consider how automation continues to reshape both food production and chemical processing industries across the world.

Dilute-Phase vs Dense-Phase Conveying: Matching Blower Type to Process Needs

Key Differences:

- Dilute-phase systems (air velocity: 15–30 m/s) rely on high-speed centrifugal blowers for lightweight materials such as flour or plastic pellets

- Dense-phase systems (air velocity: 3–6 m/s) use positive displacement blowers for fragile or abrasive materials like coffee beans or pharmaceutical granules

| Material | Optimal Conveying Method | Blower Pressure Range |

|---|---|---|

| Powdered Cement | Dilute-phase | 0.2–1 bar |

| Coarse Minerals | Dense-phase | 0.5–2.5 bar |

Case Study: Blower-Powered Conveying in Food Processing and Bulk Handling

One grain processor located in the heartland managed to slash their electricity bills by around 18 percent when they switched over to a new VFD blower system. They went with a mixed approach that combined centrifugal blowers for moving wheat across those long distances - about 450 meters worth - along with dense phase positive displacement blowers specifically for handling those sensitive spice transfers where gentle treatment matters most. According to what we've seen in real world applications of pneumatic conveying systems, this kind of setup actually boosted their capacity by roughly 22 metric tons per hour all while still keeping up with those strict USDA cleanliness requirements that are so important in food processing operations.

Wastewater Aeration: Enhancing Efficiency with Positive Displacement Blower Fans

The Role of Blower Fans in Aerobic Wastewater Treatment Processes

In aerobic treatment systems, blower fans are what actually provide the necessary oxygen for microbes to break down all that organic material. Keeping dissolved oxygen levels somewhere around 1.5 to 3.0 mg/L really matters because it allows bacteria to do their job properly. Most modern wastewater treatment facilities either use surface aerators or go with subsurface diffusers. The diffuser option needs special positive displacement blowers since they have to force air through those membranes underwater. When operators get the aeration process just right, there's significant savings too. Energy usage drops anywhere from about 22% down to as much as 50%, while at the same time Biochemical Oxygen Demand removal improves roughly between 18% and 34% when compared with older systems that don't have mechanical assistance.

Why Positive Displacement Blowers Dominate Aeration Applications

The wastewater aeration market is dominated by positive displacement (PD) blowers at around 78%, mainly because they keep delivering steady air flow even when there are changes in backpressure. Centrifugal blowers tell a different story though. When system pressure goes over 10 psi, these can actually drop performance by as much as 40%. PD units on the other hand stay pretty consistent, maintaining airflow within about plus or minus 2% variation. That kind of stability really matters when trying to maintain proper dissolved oxygen levels. Another big plus for PD blowers is that they run oil free, so there's no risk of contaminating biological treatment processes. Plus, they handle those ups and downs in workload better than most equipment. Municipal water treatment facilities have noticed tangible benefits from switching to PD technology, reporting service intervals that last about 27% longer and maintenance expenses dropping by roughly 19% compared to older systems.

Fixed-Speed vs VFD-Equipped Blowers: Energy Efficiency and Operational Control

Variable Frequency Drive (VFD)-equipped PD blowers adjust airflow dynamically, reducing energy use in aeration—which accounts for 53–60% of plant power consumption. Field data shows:

| Blower Type | Energy Use (kWh/Mgal) | DO Control Precision | Startup Torque |

|---|---|---|---|

| Fixed-Speed | 1,200–1,500 | ±0.8 mg/L | 115% Full Load |

| VFD-Equipped | 800–950 | ±0.3 mg/L | 35% Full Load |

VFD systems achieve 20–30% energy savings through turndown ratios up to 40%, while soft-start capabilities reduce mechanical stress on components.

Case Study: Municipal Plant Upgrade Using Rotary Lobe Blowers for Optimized Aeration

A Midwest wastewater facility replaced aging multistage centrifugal blowers with three 150-hp rotary lobe PD blowers equipped with VFDs and IoT-enabled pressure sensors. Results included:

- 15% reduction in annual energy use ($74,000 saved)

- 28% improvement in DO consistency during peak flows

- 30% decrease in unscheduled downtime

- Payback period under three years via rebates and operational savings

Real-time pressure mapping ensured optimal air distribution across the 12-acre basin, illustrating how modern PD systems align performance with sustainability.

Cross-Industry Uses of Blower Fans: Manufacturing, Agriculture, and Chemical Processing

Industrial Ventilation, Cooling, and Process Air: Blower Fan Roles in Manufacturing and Pharma

Manufacturing facilities rely on blower fans to keep things running safely and efficiently, mainly through control of temperature levels and air quality management. These systems are absolutely critical in pharmaceutical cleanrooms where even the slightest contamination can ruin entire batches of product during manufacturing processes. For chemical plants dealing with harsh conditions, special corrosion resistant models become essential equipment for removing dangerous fumes while also managing reactor temps when handling those intense exothermic reactions. Some recent studies suggest that switching to centrifugal blowers cuts down energy usage around 35 percent compared to older cooling techniques, particularly noticeable in places like glass kilns where heat management is so crucial. This kind of efficiency makes these fans indispensable across many different industrial settings beyond what we've already mentioned here.

- Heat extraction from CNC machines and injection molding equipment

- Combustion air supply for industrial furnaces

- Drying coated surfaces in automotive paint shops

Agricultural Aeration and Grain Handling Through Blower-Driven Pneumatic Systems

Positive displacement blowers have become essential tools for managing grains and other materials in modern farming operations. These machines help keep silo contents fresh by circulating air through stored products, which maintains proper moisture levels and cuts down on spoilage after harvest. According to some recent studies from the USDA back in 2023, this kind of aeration can actually reduce losses by around 20% or so. Farmers also rely on pneumatic conveyor systems driven by these same blowers to move things like seed stock, animal feed mixtures, and fertilizer blends throughout processing facilities at impressive speeds exceeding 30 tons per hour. This dramatically reduces manual labor requirements for big farms. When it comes to rice processing specifically, sophisticated multi-stage blower setups are used to carefully remove husks from rice grains through precisely controlled air streams. Such systems demonstrate just how versatile these technologies have become across different aspects of agricultural production.

Performance Comparison: Centrifugal vs Positive Displacement Blower Fan Technologies

Pressure, flow, and efficiency: Matching blower type to application demands

Centrifugal blowers are best suited for high-flow, moderate-pressure tasks like dust collection and HVAC, achieving static efficiencies up to 84% in optimized setups. PD blowers dominate in low-to-moderate pressure applications requiring consistent airflow under variable conditions, such as aeration and dense-phase conveying.

| Factor | Centrifugal Blowers | PD Blowers |

|---|---|---|

| Optimal Pressure | 2–12 psi | 0.5–15 psi |

| Efficiency Peak | 70–84% | 60–75% |

| Ideal Use Case | HVAC, Dust Control | Aeration, Conveying |

Lifecycle costs and maintenance: Long-term reliability of centrifugal vs PD blowers

Most centrifugal blowers don't need much day-to-day maintenance since they have fewer moving components inside. On the flip side, positive displacement blowers tend to last longer when running nonstop for extended periods, even though technicians need to check their alignment regularly to keep them efficient. Looking at what manufacturers report, PD models generally cost about 30 percent more for bearing replacements after five years of operation. But these same units often run 15 percent longer before needing major servicing in situations where they're constantly working hard. For facilities that operate around the clock, this tradeoff between maintenance frequency and overall lifespan becomes pretty important in equipment selection decisions.

Real-world data: Energy consumption analysis across industrial blower installations

A 2023 analysis of 47 facilities showed centrifugal blowers consume 18–22 kWh/ton in ventilation, while PD blowers average 12–15 kWh/ton in low-pressure aeration. However, centrifugal models regain efficiency advantages when operated above 70% load capacity, making them better choices for variable-demand settings.

Key factors influencing energy efficiency:

- Operating hours (systems running over 2,000 hrs/year favor centrifugal)

- Maintenance rigor (impacting efficiency retention by 8–12%)

- System backpressure stability (critical for PD blower performance)

FAQ Section

What are the main differences between blower fans and compressors?

Blower fans produce intermediate pressure compared to standard fans and compressors, with pressure ratios between 1.11 and 1.2. Compressors exceed pressure ratios of 1.3 and are intended for high-pressure applications.

Which blower fan type is best for wastewater aeration?

Positive displacement blowers dominate wastewater aeration applications, due to their consistent airflow and ability to handle changes in backpressure.

How do pneumatic conveying systems benefit industries like pharmaceuticals?

Pneumatic conveying systems reduce manual labor, prevent product damage, and minimize contamination during transport, making them crucial for handling delicate materials in pharmaceutical manufacturing.

How does the use of VFD systems improve energy efficiency in blowers?

VFD-equipped blowers dynamically adjust airflow, achieving 20–30% energy savings and reducing mechanical stress with soft-start capabilities.

Table of Contents

- Blower Fan Fundamentals: Types, Working Principles, and Selection Criteria

- How Blower Fans Enable Efficient Material Transport in Pneumatic Conveying

- Dilute-Phase vs Dense-Phase Conveying: Matching Blower Type to Process Needs

- Case Study: Blower-Powered Conveying in Food Processing and Bulk Handling

- Wastewater Aeration: Enhancing Efficiency with Positive Displacement Blower Fans

- Cross-Industry Uses of Blower Fans: Manufacturing, Agriculture, and Chemical Processing

- Performance Comparison: Centrifugal vs Positive Displacement Blower Fan Technologies

- FAQ Section