Understanding Upblast Fan Systems and Key Operational Components

What Is an Upblast Exhaust Fan and How It Differs from Other Ventilation Systems

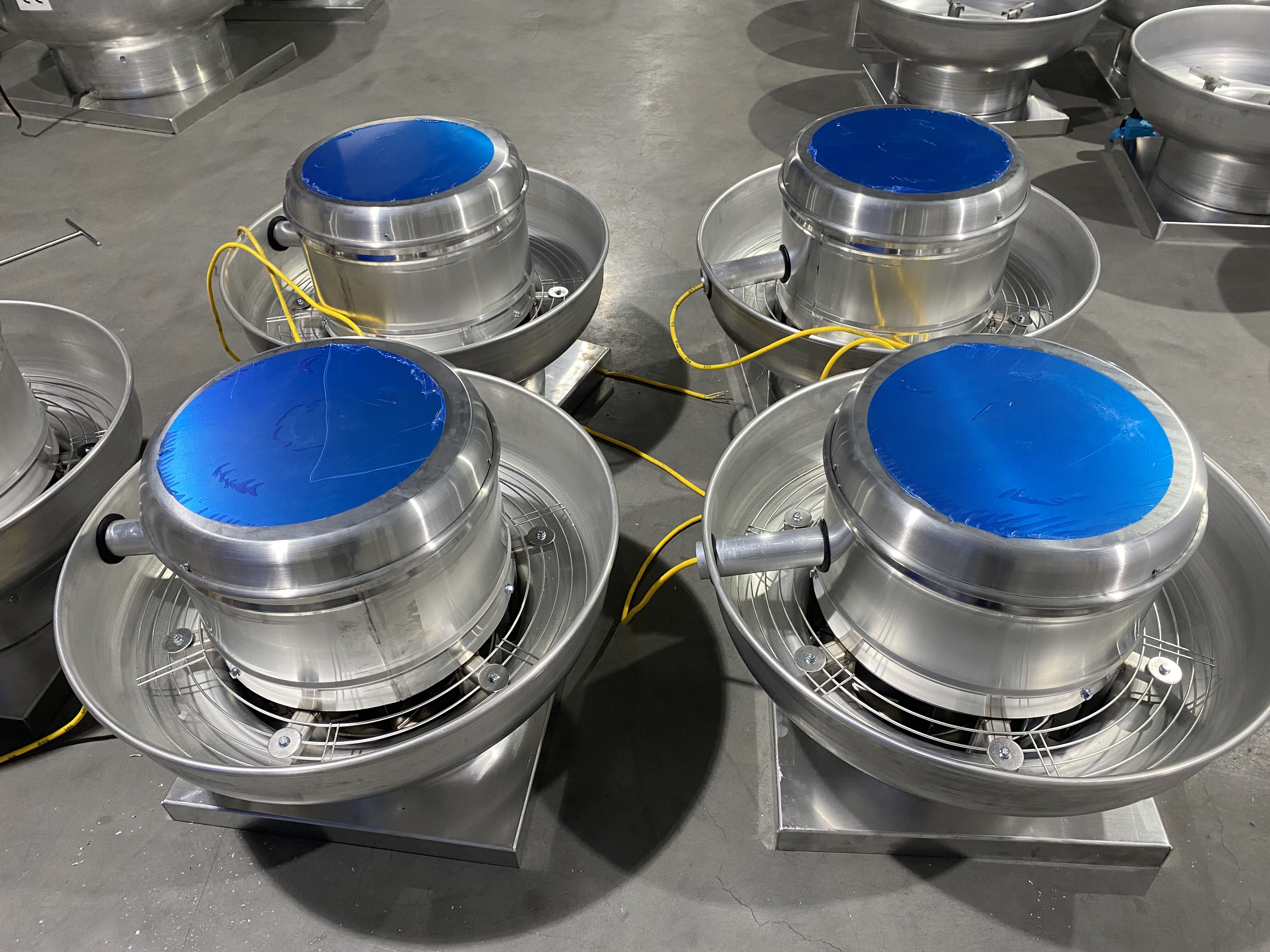

Upblast exhaust fans sit on rooftops as centrifugal ventilation systems meant for getting rid of greasy air, smoke, and heat coming out of commercial kitchens. They work differently than regular axial fans which push air along the same line as their spinning shaft. Instead, these upblast models have specially shaped blades that create what's called centrifugal force. According to Edison Parker's research from last year, they actually perform about 40 percent better when dealing with tough static pressure situations. The main parts consist of a fan bowl built to resist corrosion, plus motors and blades made strong enough to handle all those nasty exhaust fumes without breaking down. What sets these apart from ordinary ventilation setups is how seriously they take containing grease buildup and meeting fire safety requirements. Kitchens need this because the NFPA 96 regulations basically require strict control over how air moves through cooking areas to prevent disasters.

Direct Drive vs. Belt Drive Upblast Fans: Performance, Maintenance, and Use Cases

Direct drive upblast fans connect the motor right to the blade shaft, which makes them much easier to maintain compared to other types. They also run about 15 percent more efficiently when dealing with lower volume airflows under around 2000 CFM. Belt driven versions work differently though. These models have those adjustable pulley systems that let operators fine tune the fan speed precisely what many kitchen environments actually need since airflow requirements can change throughout the day. But there's a catch with belts. Maintenance folks will tell us they need checking for proper tension every three months or so, and typically replace them somewhere between once a year and once every eighteen months depending on usage. Direct drives are far less demanding in this regard, needing just an annual look at the motor itself. Looking at data from 2023 where researchers checked out 120 different commercial kitchens across the country, belt driven fans came out costing roughly 30% more over time for repairs even though they cost less initially. So it really boils down to whether a business values having that extra control worth paying more in maintenance down the road.

Critical Role of Upblast Fans in Commercial Kitchen Ventilation System Maintenance

Kitchen hood systems really depend on these fans to keep grease from building up inside the ductwork, which is actually responsible for around 28 percent of all restaurant fires according to the National Fire Protection Association's 2023 report. When upblast fans are kept in good shape, they cut down on airborne particles by about two thirds compared to those that haven't been maintained properly, something that helps restaurants stay within health code requirements. The way these fans push air upwards has another benefit too. By moving moisture and greasy stuff away from important parts of the building structure, they help prevent rusting on roofs. This simple design feature can actually make the whole HVAC system on top last anywhere between seven to ten extra years before needing replacement or major repairs.

The Importance of Preventive Maintenance for Upblast Fan Longevity

Preventive maintenance is essential for maximizing upblast fan operational lifespan while minimizing fire risks and costly downtime in commercial kitchens. Scheduled upkeep addresses wear patterns before they escalate into failures, preserving airflow efficiency and compliance with safety regulations.

How Regular Maintenance Extends Upblast Fan Lifespan and Prevents Failures

Regular bearing lubrication, keeping blades clean, and checking electrical connections go a long way toward preventing common problems like motors burning out, blocked air flow, and dangerous arc faults. Plants that stick to maintenance every six months report around half the system breakdowns seen at places waiting until something breaks down first. The numbers back this up too – when bearings get proper lubrication, energy usage drops about 18%, and motors tend to last anywhere from 3 to 5 extra years before needing replacement. These savings add up over time for facility managers watching both their equipment and bottom line.

Data Insight: Facilities with Routine Maintenance Report 60% Fewer Breakdowns

Commercial kitchens with quarterly maintenance protocols average 11.2 years of continuous upblast fan service 53% longer than the industry standard 7.3-year lifespan for neglected units. This reliability gap is especially pronounced in high-heat environments, where grease accumulation rates exceed 400% of typical exhaust levels.

Common Consequences of Neglect: Rattling, Grease Buildup, and Wiring Damage

Unaddressed issues progress predictably:

- Phase 1 (0-6 months): Vibration from unbalanced blades accelerates bearing wear

- Phase 2 (6-18 months): Grease deposits exceeding 1/8" thickness reduce airflow capacity by 30-45%

- Phase 3 (18+ months): Corroded wiring connections increase arc flash risks by 70% (NFPA 70E, 2024)

Kitchens postponing quarterly cleanings face 4.8× higher combustion incident rates compared to code-compliant operations.

Routine Inspection and Early Detection of Critical Issues

Monitoring Motor Wear, Overheating, and Unusual Noises in Upblast Fans

Proactive monitoring reduces premature failure risks by 47% in commercial kitchen environments (Facility Engineering Journal 2023). Technicians should track three key indicators:

- Temperature spikes exceeding 160°F (71°C) during continuous operation

- Vibration levels surpassing 0.25 in/sec on unbalanced blades

- Acoustic anomalies like grinding or high-pitched whining

Install infrared thermometers and wireless vibration sensors to automate data collection without disrupting kitchen workflows.

Electrical Wiring Checks to Prevent Upblast Exhaust Fan Failures

Loose connections cause 34% of preventable motor failures according to the National Electrical Contractors Association. Implement a bi-monthly inspection protocol:

| Checkpoint | Tool | Acceptable Threshold |

|---|---|---|

| Wire insulation integrity | Megohmmeter | ‰¥100 megohms |

| Terminal tightness | Torque wrench | 25-35 lb-in specified |

| Ground continuity | Multimeter | <0.1 ohm resistance |

Prioritize areas near heat sources where thermal expansion accelerates wire degradation.

Case Study: Preventing Catastrophic Failure in a Rooftop Upblast Fan System

A Midwest restaurant chain avoided $28k in downtime costs by acting on early warning signs:

Issue Timeline

- Week 1: 12% RPM fluctuation detected during automated sensor audits

- Week 3: Intermittent burning odor reported during peak service hours

- Week 5: Thermal imaging revealed a 212°F (100°C) hotspot at motor windings

Maintenance teams replaced corroded wiring harnesses and rebalanced fan blades before complete system failure occurred, demonstrating the ROI of structured inspection programs.

Fan Blade and Bearing Maintenance for Optimal Airflow Efficiency

Cleaning Fan Blades and Housing to Maintain Upblast Fan Airflow Efficiency

Grease and debris accumulation can reduce airflow capacity by up to 30%. A 3-step cleaning protocol preserves performance:

- Wipe blades weekly with non-corrosive solvents to prevent grease hardening

- Use compressed air quarterly to clear housing obstructions

- Avoid abrasive tools that scratch protective coatings

Facilities implementing quarterly deep-cleaning protocols reduce blade corrosion incidents by 70% (2024 Ventilation Efficiency Report).

Balancing Fan Blades to Reduce Vibration and Premature Component Wear

Imbalanced blades generate vibrations exceeding 0.25 in/sec in 43% of inspected systems, accelerating bearing failure. Technicians should:

- Use laser alignment tools during seasonal inspections

- Replace blades showing >1/16" deflection

- Track vibration trends using ISO 10816-3 standards

Properly balanced systems demonstrate 40% longer belt life and 22% lower energy consumption.

Bearing Lubrication Best Practices and Manufacturer Guidelines

| Factor | Guideline | Impact |

|---|---|---|

| Lubricant Type | Use NSF H1-grade grease for food-safe environments | Prevents contamination risks |

| Frequency | Relubricate every 1,000 operational hours | Reduces friction-related failures by 58% |

| Quantity | Fill 30-50% of bearing cavity | Overgreasing causes 23% of premature failures |

Facilities adhering to OEM lubrication schedules report 83% fewer emergency bearing replacements (2024 Industrial Maintenance Benchmark).

Belt Drive Maintenance: Alignment, Tension, and Replacement Strategies

Three critical checks prevent belt-driven upblast fan failures:

- Alignment: Maintain <3° angular misalignment with laser gauges

- Tension: Adjust to 1/2" deflection per 12" span (ASHRAE Standard 180)

-

Replacement: Install new belts at 90% of rated service life

Proper belt maintenance reduces drive component replacements by 55% and extends motor lifespan by 2.1 years (2023 Mechanical System Reliability Study).

Replacement Strategies and Safety Protocols in Upblast Fan Maintenance

When to Replace Motors, Blades, and Belts in Upblast Exhaust Fan Systems

Getting ahead of component failures before they happen saves everyone headaches down the road. Most motors will need replacing somewhere between 8 to 12 years if running nonstop, but things get tricky when looking at fan blades which tend to break down much quicker in greasy environments, usually needing attention every 3 to 5 years. For belts in those belt drive systems, watch out for cracks forming or when they start losing their tension grip. Experience shows these should be swapped out roughly every six months to maybe eighteen months depending on how hard they're working. Thermal imaging equipment is becoming a game changer too. These tools spot overheating issues in motors long before problems arise, catching about three quarters of all surprise breakdowns according to industry data from last year's NFPA report.

OEM vs. Aftermarket Parts: Balancing Cost and Performance in Repairs

While aftermarket parts cost 30-40% less than OEM components, third-party studies show OEM belts last 2.3x longer in heavy-duty applications. Critical components like motors and bearings should prioritize OEM specifications to maintain airflow efficiency and UL compliance. Non-load-bearing parts (housing fasteners, gaskets) safely accept generic alternatives.

Essential Safety Procedures Including Lockout/Tagout During Maintenance

NFPA 96 standards mandate lockout/tagout (LOTO) protocols during all upblast fan servicing. Facilities using documented LOTO procedures reduced maintenance-related injuries by 84% (2024 industrial safety audit). Always:

- Verify electrical disconnect before blade cleaning

- Use fall protection harnesses for rooftop units

- Install grease shields prior to housing removal

Documenting Inspections and Repairs for Compliance and Service Tracking

Maintain digital logs detailing blade balance tests, belt tensions, and motor amp draws. Cloud-based systems automatically flag components nearing replacement thresholds. Fire marshals require 3-year inspection archives paper-based systems increased compliance fines by 61% versus digital tracking (International Kitchen Exhaust Association, 2023).

FAQ

What is the primary function of upblast exhaust fans?

Upblast exhaust fans are designed to remove greasy air, smoke, and heat from commercial kitchens to prevent grease buildup and fire hazards.

How do direct drive and belt drive upblast fans differ in maintenance requirements?

Direct drive fans connect the motor directly to the blade and require less frequent maintenance. Belt-driven fans have adjustable pulleys and need regular tension checks and belt replacements.

How often should upblast fans undergo preventive maintenance?

Upblast fans should undergo preventive maintenance every six months to ensure optimal operation, prevent grease buildup, and extend the lifespan of components.

What are common signs that an upblast fan needs maintenance?

Signs include unusual vibrations, excessive grease buildup, reduced airflow, and signs of corrosion or damage to electrical wiring.

Why is routine inspection important for upblast fans?

Routine inspections help in early detection of issues, reduce failure risks, and ensure compliance with health and safety codes.

Table of Contents

- Understanding Upblast Fan Systems and Key Operational Components

- The Importance of Preventive Maintenance for Upblast Fan Longevity

- Routine Inspection and Early Detection of Critical Issues

- Fan Blade and Bearing Maintenance for Optimal Airflow Efficiency

- Replacement Strategies and Safety Protocols in Upblast Fan Maintenance

-

FAQ

- What is the primary function of upblast exhaust fans?

- How do direct drive and belt drive upblast fans differ in maintenance requirements?

- How often should upblast fans undergo preventive maintenance?

- What are common signs that an upblast fan needs maintenance?

- Why is routine inspection important for upblast fans?